LED Explosion-proof Lighting – Procurement Guidance

The best explosion-proof lighting factory manufacturer directly explosion-proof led supplier led flood light with the certification

Why is explosion-proof lighting important in dangerous places?In LPG processing plants, paint spray booths, gas stations, chemical plants, or laboratories, combustible gases, dust, and volatile organic chemicals are everywhere.Sparks from the lamps can ignite explosive vapors with deadly consequences.Therefore, intrinsically safe lighting is crucial in this industrial explosive environment.In addition, our lamps also have external explosion-proof function.It minimizes worker casualties by providing bright lighting for evacuations and other emergencies.Lighting security for special occasions is a necessary factor to consider.

What is explosion-proof ceiling luminaire?

High ceiling is one of the common types of indoor lighting fixtures.They are designed for high ceilings up to 6 to 20 meters high.Explosion-proof lighting is required in warehouses or storage units containing flammable materials or combustible fibers.The LED in the explosion-proof high shed has high luminous efficiency, so the power input of the lamp is low.In addition, due to the unique LED packaging, the lights do not spark when we turn them on or use them.It makes our LED products inherently safe.

In the past, the use of halogen or metal halide lamps in such hazardous locations was extremely dangerous, as the filament immediately generated a high temperature (2000-3000 °C) when the high-powered bulb was turned on.A spark will ignite combustible particles or gases in an explosive gas. LED, however, solve this problem by using a completely different mechanism – using an electric current to flow through the semiconductor to produce visible light rather than heat.The junction temperature of the lighting equipment can be greatly reduced, thus making it safer in an explosive environment.The heat buildup of the high ceiling lights can also damage the chips, so we have a patented radiator design that radiates heat away to keep the lights cool.

Classification and division of explosion-proof lighting requirements

According to the U.S. Occupational Safety and Health Administration, there are several categories of hazardous sites.Custom lighting should be used in different explosion environments.

1.Level 1 and level 2 explosion-proof lighting

Levels 1 and 2 are the most common classifications of risk areas.The class 1 describes the location of a combustible gas mixture in the air.If there is a fire, the concentration is high enough to trigger an explosion.In contrast, a level 2 area indicates the presence of flammable dust or powder.Therefore, we can see that the main difference between class 1 and Class 2 locations is the state of flammable substances.One is a gaseous or volatile mixture, while the other is a powdery particle.Therefore, since gaseous materials can be easily dispersed in the air, we can see that deflagration is more likely to occur at stage 1 than at stage 2.For level 1 locations, the explosion protection requirements for lighting will be more stringent.

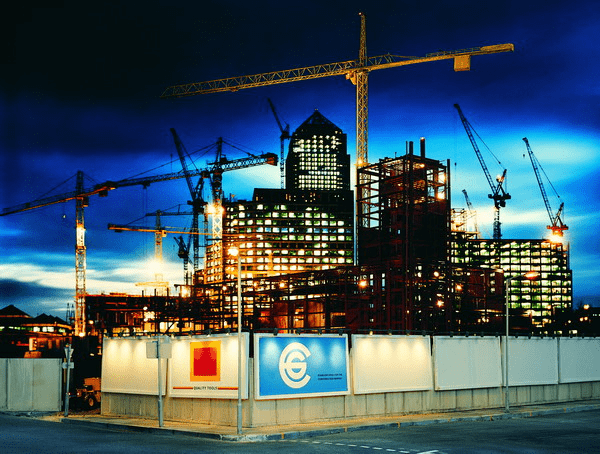

Examples of type 1 sites include LPG processing plants, gasoline plants, pipeline stations, oil refineries, spray paint houses, etc.

Examples of type 2 environments include coal mines, pyrotechnics, food processing plants (flour, sugar, starch storage), etc.

2.What is category 1?

The location of zone 1 of class 1 describes the area where combustible gas may occur if the machine is operating under normal or abnormal conditions.

3.What is category 1 and Category 2?

Stage 1 Div 2 means that combustible gas or steam will remain inside the containment, but if the containment fails, those explosive substances may leak out of the containment vessel.

4.Level 1 Div 1 and 2 Diving lighting

You might ask, what’s the difference between level 1 div 1 and Div 2 position lighting?By the definition above, we need to expect the explosive material to always be in the 1-lattice 1-lattice region.The chance of an explosion is relatively high.For level 2 div 2, the combustible mixture may be confined in a closed system.However, leakage can also occur if the shutdown system fails.Although lighting at div 1 and DIV 2 locations is inherently safe, Div 1 lighting should have a higher explosion-proof standard.

Pls check the blew link to see the product detail information:

5.What is type 2 Zone 1 environment?

Unlike class 1, Class 2 Div 1 describes the presence of flammable dust or powder in the air in normal or abnormal working conditions.

6.What is category 2 and Category 2?

Div 2 position is relatively “safe” and flammable dust will not be found in the air unless there is a malfunction with the equipment.However, we should also be prepared for explosion-proof lighting in these areas because of combustible dust in the workplace.

7.Class 2 Div 1 and Class 2 lighting

Which is the most dangerous between level 1/2 and div 1/2?In order to compare the four classifications, the degree of explosion difficulty is arranged in the following order: 1 category 1 classification & GT;Class 1, Classification 2 & GT;2 Category 1 Classification & GT;2 Category 2 Classification.

Why are our LED light explosion-proof

1.Polycarbonate on LED light house

To be bulletproof, we need to prevent the projectile from penetrating the light fixture.

Bulletproof lenses are made of two materials — glass and elastic polycarbonate. They are laminated to form alternate layers.The protection increases with the thickness of the sandwich lens.

If you shoot a bullet through the lens, the elastic polycarbonate layer will bend the glass and absorb energy.The bullet slowed and stopped before it had fully penetrated the lens.

2.Intrinsically safe light

In zone 1, the room may be filled with combustible gas, steam, and dust.We need to make sure that the light fixture doesn’t generate any sparks.Otherwise it will ignite the substance and cause a fire or even an explosion.With the 170 LM/W LED chip, we can keep the power input at a very low level.In addition, LEDS don’t produce much heat in the body of the lamp.Therefore, our LED lights are safe in nature.

3.No copper and aluminum light house

Our explosion-proof lamps are made of copper-free aluminum alloy – an alloy containing less than 0.35% copper, which has proven to be of greater strength and durability.

4.Patent structure design

Our LED lights use a patented aerodynamic design that effectively reduces the junction temperature of the lighting chip.Lower operating temperatures mean more safety.

5.Compliance with UL&OSHA standards

Our LED lights meet UL standards – when switched on, they do not ignite gas, dust or other flammable substances.

Best 12 best explosion-proof and hazardous lighting

1.Paint room lighting

Spray booth is a common application of explosion-proof lamps.Lighting is essential for paint spraying because it allows us to observe the true color and distribution of paint.We will need to examine the surface treatment carefully to avoid any defects.In addition, the coating contains highly flammable chemicals such as propane, methane and other organic solvents.Because they are volatile, they can diffuse in the air.A small spark can cause an explosion, which can have tragic consequences.Therefore, the need for inherently safe paint room lamps.

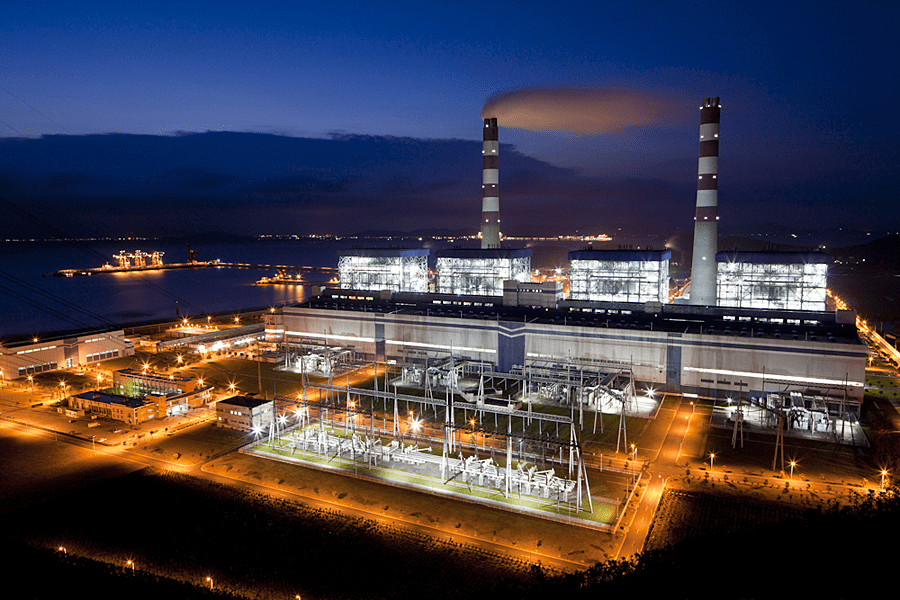

2.Nuclear power plant lighting

Explosion-proof lighting is widely used in nuclear power plants for the following reasons.

a.security

To be blunt, explosion-proof lighting in nuclear power plants provides greater safety because they are designed to avoid/prevent explosions.As with any industry, damage and explosions are considered the most serious threat to all nuclear plants.

Needless to say, nuclear power plants are more prone to accidental explosions because the environment is always full of harmful gases and dangerous substances.That is why a high level of safety guidelines should always be maintained in nuclear power plants to eliminate the possibility of accidents and serious human consequences.Now, to maintain appropriate safety standards for nuclear power plants, it is always recommended to use lighting that prevents and reduces the possibility of explosion.

b.Ruggedness ensures longer life

The main advantage of explosion-proof lighting lamps is safety;However, such lighting solutions have other advantages that you should be aware of.For example, they are strong and durable.Technically, they are designed in such a way that they can easily withstand the harsh conditions of a nuclear plant and provide a longer life.In addition, they are dust-proof, waterproof, anti-corrosive and wear resistant.In addition, they ensure stable performance throughout their service life.

c.Exquisite design, easy to operate and compact size

These explosion-proof and accident lamps are of exquisite compact design.They are easy to operate, light in weight and small in size.Most of them have excellent heat dissipation performance.In addition, they produce uniform lighting so that workers inside the plant never face fatigue or eye discomfort.

Considering the above advantages, explosion-proof lamps are considered to be very important for the use of nuclear power plants.

Pls check the blew link to see the product detail information:

3.Casting explosion-proof lights

There is no doubt that the explosion is closely related to the lighting system that generates heat.This is more real and applicable to a foundry because of the hazardous environment in which the foundry operates.

The safety and security of employees is Paramount and there can be no compromise.

LED that provide the best explosion-proof lighting are no longer a luxury, but at least a necessity.We had to consider the overall size of the foundry, ventilation and other facilities before deciding what type of LED-driven lighting system.

The initial cost may be an issue, but it must provide benefits through the security of the entire unit and the resulting repeated cost savings, which are important to keep in mind.

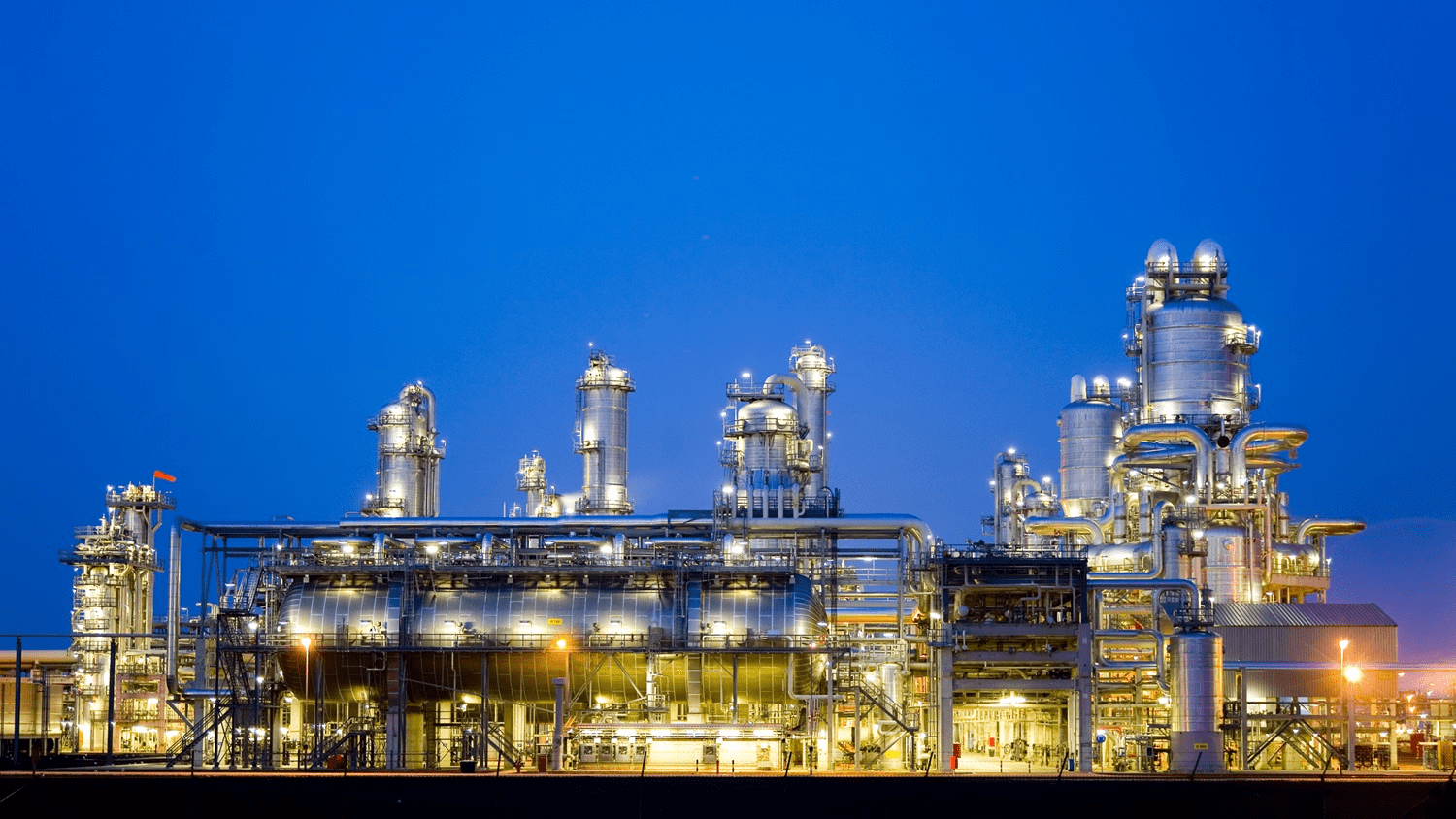

4.Refinery LED lighting

As we all know, there are many hazards in oil refineries.There is always a risk of fire or explosion in a refinery because it involves many toxic and flammable ingredients such as petroleum solvents, lubricants, fuels, oils and waxes.Another hazard of any crude refinery happens to be the risk of exposure to toxic chemicals, which can lead to corrosion, asphyxiation and combustion.

A work permit is required to operate in such an area and must always be safe.Below, we will discuss why explosion-proof lighting currently plays an important role in oil refineries.

a.Protect employees

The use of explosion-proof lighting in these hazardous areas minimizes the risk of explosion that may occur as a result of the above.The lighting will ensure the safety of all workers in the factory.If workers use lightning arresters, any disaster in a confined space can be avoided because lightning arresters can avoid catastrophic rupture due to flammable materials.But these explosion-proof lamps also offer benefits that go beyond worker safety.

b.durable

Another reason individuals seek lamps that will survive an explosion is that they are intrinsically highly resilient.You will encounter several types of lighting that will start to fail as soon as they collide or jolt and may need to be replaced regularly.But they are durable and rugged, which means they will be able to withstand the kind of interactions that are common in oil refineries.

c.High efficiency and energy saving

Third, another important benefit of using explosion-proof lighting in refineries is that they happen to be more energy efficient.In fact, the EPL USES 85% less energy than conventional lamps.In this way, the running cost of lighting can be reduced.

5.Industrial chemical plant light

The chemical plant will do a lot of harm to the employees who work there.However, risks can be minimized by taking appropriate measures.One such initiative will be the use of a sophisticated and innovative EPL LED lighting system.These lights will have a positive impact on workers’ performance compared to traditional incandescent bulbs there, and they will last longer.LED EPL relies on rugged design to actively prevent spark and ignition.In this context, the term “explosion-proof” actually refers to the ability of the device to isolate the spark within the lamp itself, within which it is impossible to react with any flammable substance.Most of these lighting systems are housed in thick glass enclosures, and explosion-proof boxes can also be used to accommodate sensors, switches and wiring.It is essential that these products do not allow any gas into the aluminum casing.

Having experienced all the advantages of explosion-proof lighting, it is clear that this trend will continue in the future, which will help to minimize the possibility of hazards occurring in chemical plants.

6.Bank vault lighting

Explosion-proof lamps are one of the safest lamps on earth.The remaining question is, are bank vaults required to be the same?There is no doubt that bank vaults need explosion-proof lights.It not only improves security, but also ensures proper lighting throughout the day and night.With their many advantages, they should be an integral part of every bank’s security system.In this article, we delve into the importance of flameproof lights and can help you understand why flameproof lights are great for bank vaults.

7.Office of key Government Officials

Lighting that works in an explosion is also important for government offices like the White House.In the event of a riot, the gangsters may throw stones or even shoot at government offices.As a result, lighting has become the last line of defense in these areas.

8.Laboratory lights (indoor and outdoor)

The danger and complexity of the laboratory pose a variety of dangers to scientists and workers, including explosions and fires.While there are many options available to enhance security, lab flameproof lights are certainly one of the best precautions you can take.With advanced LED technology, they are a robust, reliable and cost-effective solution to prevent ignition of dust particles and combustible gases.

In addition, visibility and mobility restrictions in closed laboratories make explosion-proof lighting essential for chemical processing activities.Their adoption not only increases overall lighting capacity, but also enhances safety, enabling scientists to work safely and effectively.

9.Plumbing station lighting

Explosion-proof lighting makes work easier and safer in dangerous places such as pipe stations.Gone are the days when plumbers had to work under high stakes and exercise extreme caution.Today, workers are not only safer, but also better able to concentrate and ultimately become more productive.

You will agree that safety and security can improve the work culture.Therefore, it is not only important but also necessary to use this particular type of lighting for dangerous workplaces such as plumbing stations!

10.Mining site

EPL LED lighting systems are generally more durable and pose no risk in narrow and dangerous situations such as mines.They are not easily touched or pushed, and they do not need to be replaced from time to time.These lamps are extremely strong and resilient, which means they will be able to withstand any interaction in case they are hit by a worker or any fragile component falls on them.They are also more energy efficient than ordinary incandescent or halogen bulbs.In addition, they have a lifespan of nearly 80,000 hours in some cases.Last but not least, their better efficiency and durability will greatly reduce maintenance costs.

11.LPG processing facilities

LPG is a highly flammable gas.If there is a spark in the lighting at the LPG processing plant, it will be extremely dangerous to the workers and the facility.In such a fire hazard environment, intrinsically safe LED lights are required.LED use less power to produce the same brightness as conventional halogen bulbs and metal halide lamps.This is the main reason why LED lights are highly unlikely to explode.In addition to improving energy efficiency, LED chip junction temperatures are generally lower than HID lamp junction temperatures.They have a lower temperature and are therefore safer.

12.Offshore oil and Gas table lights

For years, the oil and gas industry relied entirely on conventional forms of lighting, such as fluorescent lamps.Not only do these lights suffer from sky-high replacement costs, but they also lack explosion-proof functions, putting the lives of workers working on offshore oil and gas platforms at risk.Explosion-proof lighting technology has recently struck a chord among oil and gas operators.More specifically, the downward trend in oil and gas prices is forcing operators and buyers to reduce overall costs by turning to financially viable options.In such cases, these lights have become ideal for operating companies.

Advantages and disadvantages of using explosion-proof lamps

In many hazardous areas, the use of conventional lighting systems may not be considered safe and is therefore generally not recommended.These areas are classified as high-risk because there is always a risk of explosion.These can be caused by a variety of reasons.It can be caused by an explosive substance such as fog or dust, or by flammable gases that can ignite even at the slightest provocation.Although such hazardous environments and areas are not found in domestic Settings, they can be found in many industrial and manufacturing sites.The list is large and may include drilling RIGS, oil refineries, power generation facilities, chemical plants and storage units.

1.How to ensure the safety of dangerous places

There are clearly defined norms and agreements, which must be strictly observed without any deviation.There are special fire drills going on, and other safety measures to prevent sudden, unexpected, and potentially fatal fire outbreaks.We also need to remember that existing lighting arrangements also play an important role.Therefore, the authorities strongly recommend that even the proper installation of explosion-proof lights and other systems be obligatory.

These lighting systems have special functions and are known for their ability to prevent the surrounding environment from overheating, as many lighting systems and devices are notorious for generating heat.Such heat can have a catastrophic effect on entire areas where hazardous chemicals are located or where they are manufactured, stored or even refined.Therefore, various other options need to be identified, and the focus is now on looking at other lighting devices that produce low heat.We will examine the various advantages and reasons for installing such a low-calorie lighting system.

We are confident that the information provided below will help readers and even other stakeholders understand the benefits of specially designed lighting systems, while keeping in mind the risks associated with these high-risk areas.As far as these lighting systems are concerned, there are some drawbacks, and the same issues will be discussed in detail.

2.Installation of explosion-proof lighting advantages

They produce less heat.Most of these explosion-proof lamp solutions are LED technology.Clearly, LED lighting systems have some obvious advantages and benefits.

Pls check the blew link to see the product detail information:

a.Fewer calories

First, they produce far less heat than conventional lighting systems, such as fluorescent and conventional bulbs or incandescent bulbs.These yellow or halogen lamps are particularly noted for their thermal power.Therefore, do not use them in such a high-risk and dangerous place.LED, by contrast, are known for their soft impact and do not cause the surrounding environment or ambient temperature to rise.They produce high quality light and illumination.It is often necessary to strike the right balance between reducing the heat generated by these lighting systems and meeting lighting requirements, which is a big problem.However, when you choose general explosion-proof lighting, especially LED lighting,

b.No filaments

These lighting systems are better able to withstand vibration than other forms of lighting.They don’t have any glass parts or filaments.As the heat increases, this reduces the risk of the glass exploding and the risk of the filament slipping out of its socket.This undoubtedly gives these lighting systems a higher threshold to withstand rough handling than standard lights.This is a very important and vital function, especially in closed, poorly ventilated and secluded enclosed Spaces.As a result, their rugged appearance, ability to withstand harsh conditions and other similar features make LED lights a good choice for hazardous areas.

c.LED never explodes

They have proven energy saving properties and characteristics.These lighting systems emit about 3.4 BTU per hour.They are also insensitive to external temperature and humidity.As a result, LED will never explode and become a cause of fire and other related hazards when the external temperature rises beyond an acceptable safe level.Carbon dioxide emissions are also a major risk for many conventional lighting systems.We all know that the gas is flammable and if the external temperature is very high, it can have disastrous consequences.

d.The LED is free of mercury and lead

In general, LED lighting systems, and those designed for lighting in hazardous locations, also have another advantage.They are completely free of harmful metals such as mercury and lead.Although mercury itself may not be flammable, it can be a highly dangerous combustible when in contact with vapor fog.Therefore, it is generally recommended that most hazardous sites, such as LPG bottling plants, crude oil refineries and other similar sites, be kept away from mercury lamps.In the event of a fire, lead may give off toxic substances, which may cause many problems.

3.The shortcomings

It is wrong to mention that the LED lighting system has no defects or shortcomings.As far as LED lights are concerned, there are some disadvantages. Here are some of them:

Price is usually one of the main disadvantages of LED lighting systems, especially explosion-proof lighting equipment.Therefore, a proper balance between costs and benefits needs to be struck.In some cases, high external temperatures can cause LED lighting system failures.When we look at the risks associated with lighting systems in combustible and other hazardous locations, it is clear that choosing the right explosion-proof lights is critical.Although there may be a cost factor involved in such a lighting system, in most cases it is an initial investment.These LED lighting systems save a lot of money by reducing electricity costs.Most importantly, dangerous environments and other such areas become safer in terms of fire breaks and other such hazards.Therefore, when the final judgment is made, these lighting systems are considered a better choice than conventional lighting.

Conclusion:

Our green light team is committed to developing safe and energy saving lighting solutions for our customers. Please contact our team for satisfactory design solutions.[email protected].